Products

Learn more about the Changsha 3 Better Ultra-Hard Materials Co. Ltd products.

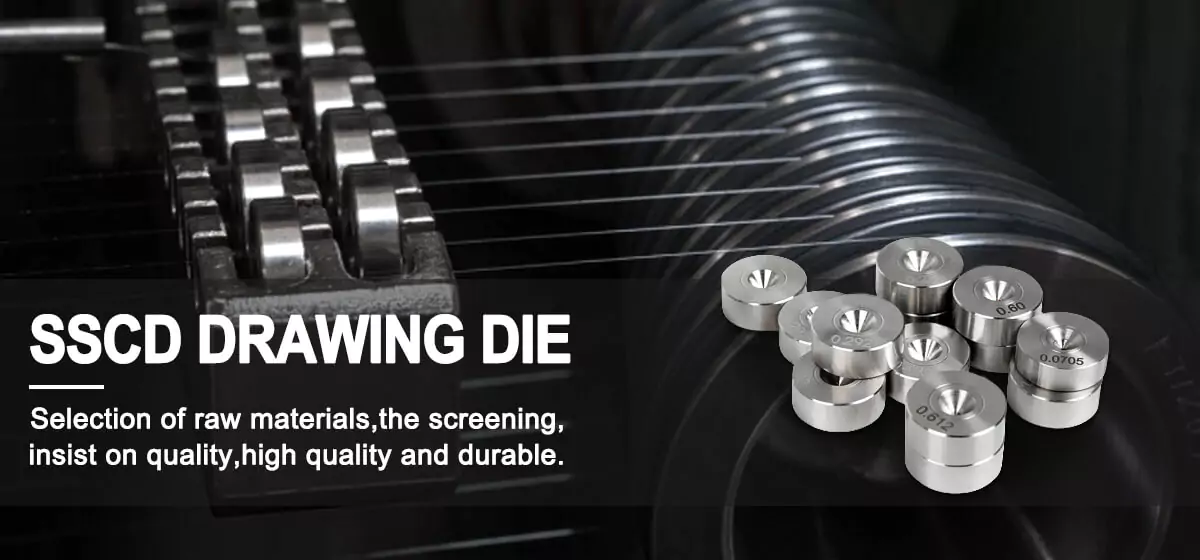

SSCD Wire Drawing Dies

Synthetic single-crystal diamonds is an ideal choice for manufacturing fine steel wires and ultrafine wire drawing. SSCD dies have excellent quality, hardness, accuracy, and service life.

| Full Name: | SSCD(Synthetic single crystal diamond wire drawing die) |

|---|---|

| Size: | Hole 0.04mm-1.5mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | Stainless steel outer case+Monocrystalline Diamond die blank |

Description

| Full Name: | SSCD(Synthetic single crystal diamond wire drawing die) |

|---|---|

| Size: | Hole 0.04mm-1.5mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | Stainless steel outer case+Monocrystalline Diamond die blank |

The Description of SSCD drawing dies.

Synthetic single-crystal diamonds, also called synthetic mono crystal diamond, and abbreviated as SSCD, SMCD, MCD, or AD. The die blank used: a single crystal diamond, which is a kind of synthetic diamond under controlled conditions. It has high purity, no impurities, and no cracks characteristics. SOMEBETTER SSCD drawing dies are manufactured with a mirror polish and a smooth wire entry to ensure optimal die life and string-up.

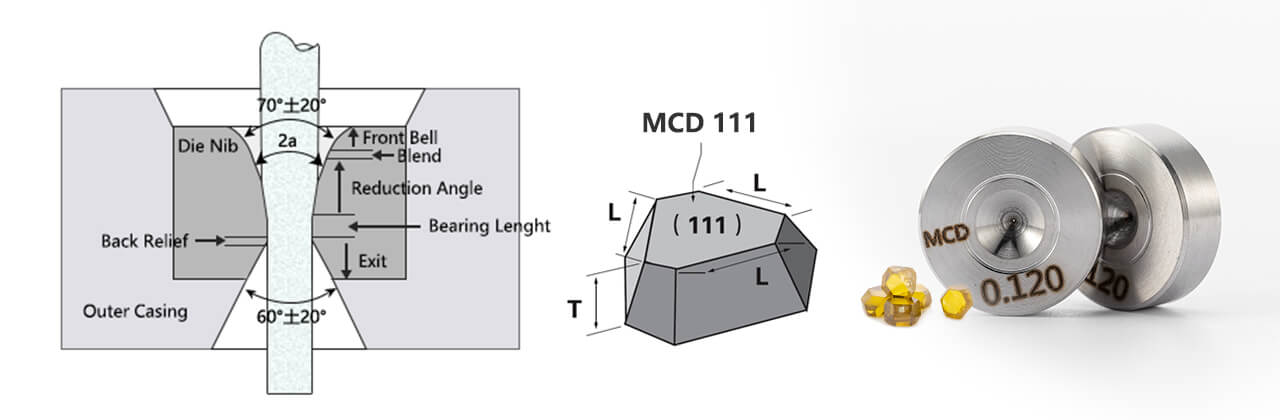

The Advantages of SSCD drawing dies.

- The use of 111-sided synthetic single crystal diamond as the die blank, the production of dies positioning accurate, stable performance.

- Extremely high hardness and wear resistance ensure the long life of the dies.

- Single-crystal diamond has excellent thermal performance for high-temperature processing.

- High hardness, good wear resistance, high efficiency, and longer lifetime.

The Shapes/drawing Reference of SSCD drawing dies.

| Reduction Angles & Bearing Length of SSCD Drawing Dies | |||||||

| Elongation | Area Reduction | Bearing Length | Lead Zinc Silver Gold | Hard-Alalloys Nickel Copper | Brass Cualloys Stainless Steel | High Carbon Steel | Hot Tungsten |

| 5-9% | 5-8% | 0.2-0.5d | 14° | 10° | 9° | 8° | 10° |

| 9-14% | 8-12% | 0.2-0.5d | 16° | 12° | 13° | 10° | 10° |

| 14-19% | 12-16% | 0.4-0.8d | 18° | 14° | 13° | 12° | 12° |

| 19-33% | 16-25% | 0.4-0.8d | 22° | 18° | 16° | 15° | 12° |

| 33-54% | 25-35% | 0.4-0.8d | 24° | 22° | 19° | 18° | 14° |

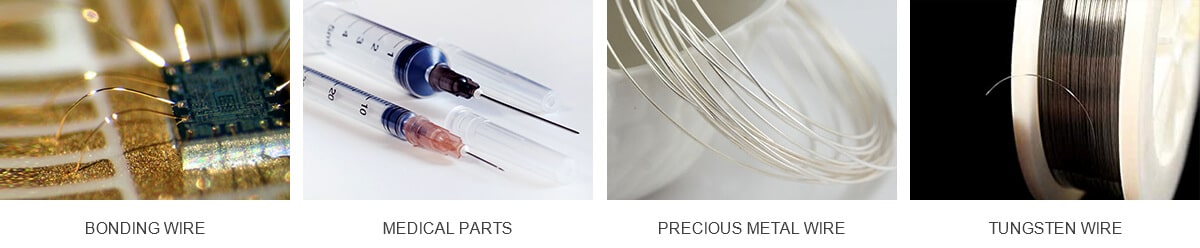

The Application of SSCD drawing dies.

Semiconductor bonding wire (gold, copper and aluminum), Medical wire, Stainless steel wire, Copper wire, Special alloy wire, and Precious Metal wire.A variety of other colored or non-ferrous metal wires.Low, medium, high-speed,single&multi-head wire drawing machine

Production Process of SSCD drawing dies.

The drawing dies manufacturing steps of 3 BETTER Drawing Die Factory: select the appropriate drawing die blank and insert it into the drawing die outer casing, and then conduct a series of processing procedures such as trumpet entrance, laser drilling, grinding (rough grinding, fine grinding, finish grinding), grinding, marking, etc. for the die, and then use professional testing equipment to inspect the quality of each finished die.