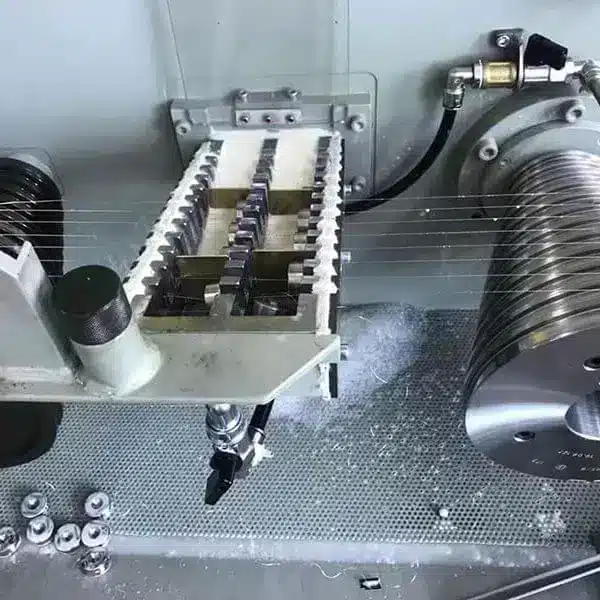

The nano-diamond composite coating drawing die is based on cemented carbide (WC-Co), and chemical vapor deposition (CVD) is used to carry out micron-level and nano-level diamond composite coating on the inner hole surface of the mold. A brand-new mold is obtained after the precision grinding and polishing of the coating. The micro-nano composite coating on the surface of the inner hole not only has the characteristics of strong adhesion and good wear resistance of the micro-diamond coating, but also has the advantages of high surface finish, small friction coefficient and easy grinding and polishing of the nano-diamond coating.

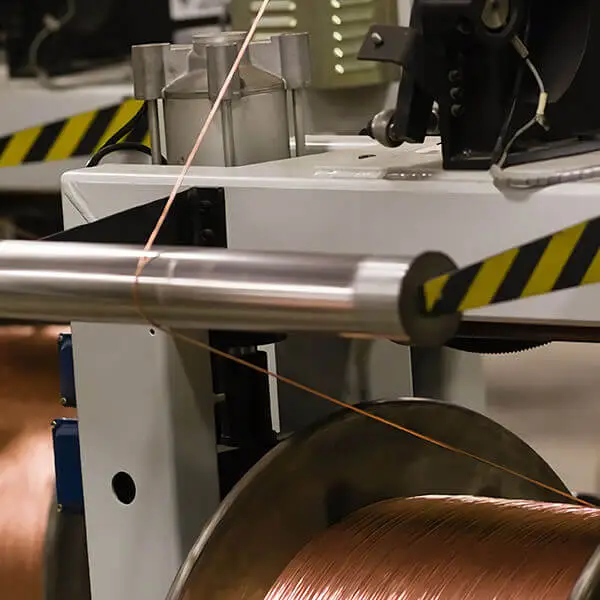

Using this die to draw aluminum wire is more than 30 times that of cemented carbide molds; drawing low carbon steel wire is more than 20 times that of cemented carbide molds; drawing medium carbon steel wire is more than 30 times that of cemented carbide molds

2) Hole diameter change when the mold is scrapped: 0.00 mm, maintenance-free mold

3) The finish of the working surface is high and always unchanged

4) High dimensional accuracy (because of computer-aided detection)

Using it in the actual production process can reduce the number of shutdown inspections and mold changes, thereby greatly improving production efficiency

2. Saving raw materials, the length of the wire produced is 1%~2% longer than that produced by traditional molds.

3. Improve product quality (because of high working surface finish and high dimensional accuracy)

4. Save electricity