Products

Learn more about the Changsha 3 Better Ultra-Hard Materials Co. Ltd products.

Nano-diamond coating drawing die

The nano-diamond composite coating drawing die is made of cemented carbide (WC-Co) as the substrate, and the surface of the inner hole is coated with a micro-nano-scale diamond composite coating by chemical vapor deposition (CVD), which is ground and polished.

| Full Name: | Nano diamond coated die/CVD Coated Diamond Die |

|---|---|

| Size: | Hole 0.15mm-55mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | Stainless steel outer case+ Tungsten carbide+Nano coating |

Description

| Full Name: | Nano diamond coated die/CVD Coated Diamond Die |

|---|---|

| Size: | Hole 0.15mm-55mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | Stainless steel outer case+ Tungsten carbide+Nano coating |

The Description of Nano-coated drawing die.

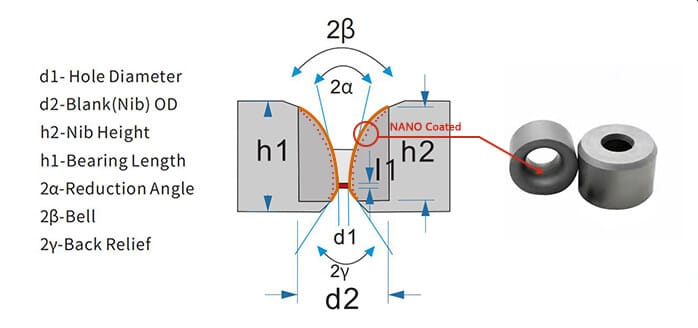

The nano-diamond coating drawing die has cemented carbide (WC-Co) as the substrate. The surface of the inner hole is coated with a micro-nano-scale diamond composite coating by chemical vapour deposition (CVD), which is ground and polished.

The Advantages of Nano-coated drawing die.

- Targeted pre-treatment process: make the coating and substrate closely combined.

- The bottom micron diamond coating has excellent wear resistance.

- The surface nano diamond coating provides an excellent surface finish and low friction coefficient.

- Computer simulation and optimization of hole design: high dimensional accuracy, uniform stress on the wire rod, saving raw materials.

- There is no change in the diameter of the die from use to scrap, reducing the times of downtime inspection and drawing die change and improving production efficiency.

- With a wider diameter range, service life is 5 to 10 times that of tungsten carbide.

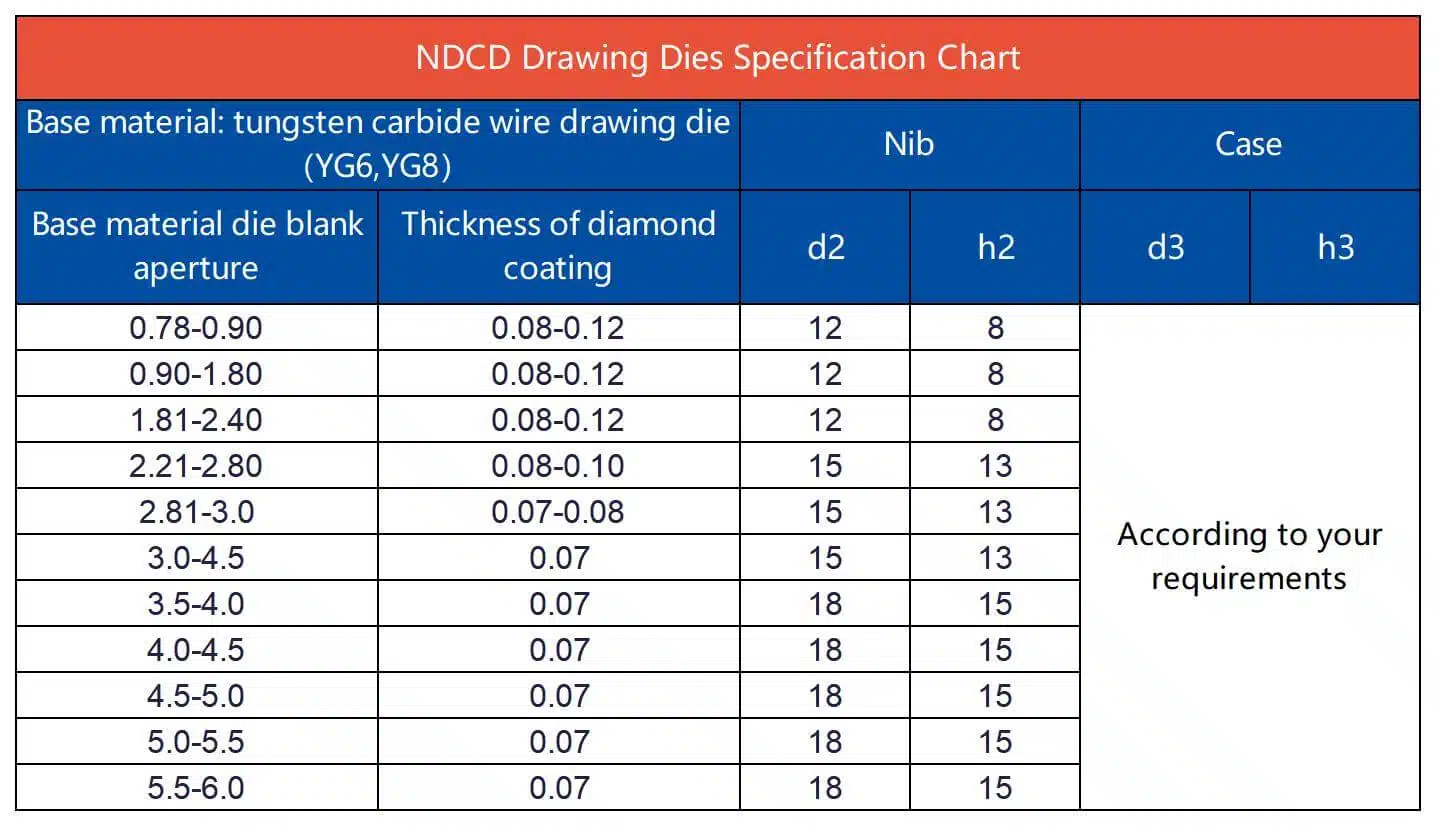

The Specification of Nano coated drawing die.

Test report of Nano coated drawing die.

Test report of Nano-coated drawing die: Nano-coated-drawing-die-Test-Report.pdf.