Wire drawing dies are a critical component in steel wire production, and the quality of finished steel wire is closely tied to the performance and efficiency of the dies. To reduce die consumption, improve production efficiency, and lower labor intensity, it is crucial to address issues such as excessive wire diameter deviation, increased breakage during drawing, and reduced wire sizing rate.

Heat treatment

The steel wire is usually drawn in a tank below the recrystallization temperature of carbon steel, which belongs to the cold working range, and to prevent the metal from working hardening and cannot return to crystallization, it is necessary to use a sostenite with a high cold working limit. We can increase the sostenization rate of semi-finished steel wire to a higher level by adjusting the furnace pressure, furnace temperature, lead temperature and wire take-up speed, so as to improve the sostenization rate of semi-finished products.

Phosphating state

The thickness and stability of the phosphate film will also affect the inverted steel wire drawing, when the phosphate film on the surface of the semi-finished steel wire is thin or not firm, the drawing process will damage the wire drawing die and cause the steel wire diameter to be out of tolerance or scratches on the surface. At this time, we can increase the surface quality of the phosphate film by adjusting the total acidity of the phosphate solution, stabilizing the total acidity and the concentration of free acid.

Lubricating fluid concentration

The use of wet drawing lubricant in the water tank drawing machine can reduce the friction factor of the contact surface between the steel wire and the die during the drawing process, and form a certain thickness of lubricating film between them, which can reduce the loss of the drawing die. The quality fraction of wet lubricant in the lubricating fluid is also one of the key factors affecting the drawing speed of the steel wire, and the lubricating fluid should be added and tested regularly by specialized personnel to ensure the quality of the wet lubricant in the lubricating fluid.

Lubricating fluid temperature

The steel wire will heat up due to its own deformation and friction with the inner wall of the dies during the drawing process, and the temperature of the steel wire will be higher after multiple passes, if it is not cooled down in time, it will cause lubrication failure and shorten the life of the dies. In order to ensure the speed of wire drawing, the lubricating fluid in the water tank wire drawing machine should be circulated to stabilize its temperature. This is the need to regularly overhaul the circulating equipment and lubricating fluid temperature to ensure that the drawing speed is stable.

Drawing process

In the drawing process, the total compression rate of steel wire raw materials can not be too high, through the redistribution of part of the compression rate, so that part of the compression first small and then large and then decreasing in turn, the principle of ensuring that the surface lubrication layer of the first semi-finished steel wire is not destroyed, so that the second pass makes full use of the plasticity of the steel wire to avoid work hardening and gradually reduce the part of the compression rate. This drawing principle can ensure that the steel wire obtains better comprehensive mechanical properties and reduces the energy consumption of the equipment.

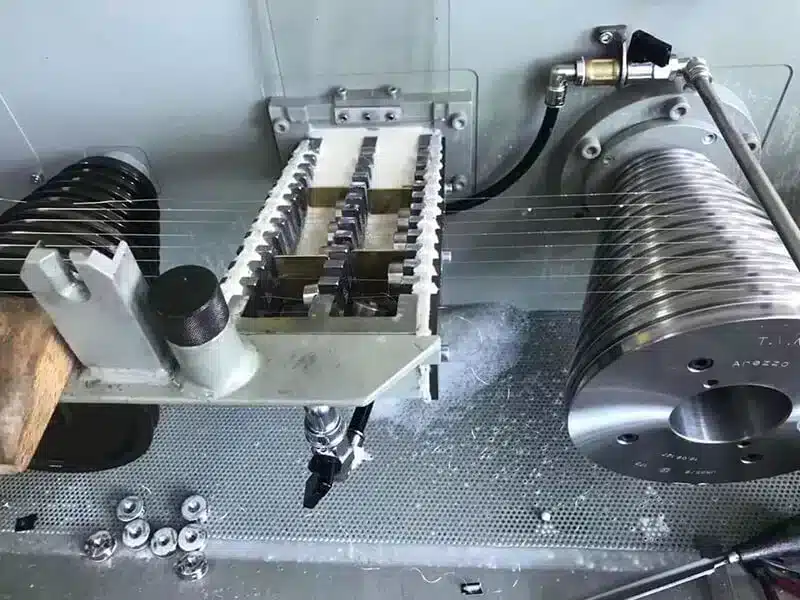

The choice of wire drawing die

Medium and high carbon steel wire will produce a lot of heat in the drawing process, in addition, there is mutual friction between the steel wire and the drawing die, so the tungsten steel dies with high hardness, good wear resistance, high thermal conductivity and low cost should be used. In order to improve the service life of the wire drawing die, the curved type can also be changed to a straight working area, so as to reduce the wire drawing resistance, increase the height of the working area, and reduce the loss of the wire surface coating of the wire drawing die.

Maybe you’ve been concerned about broken wires.

Regarding wire breakage, we have analyzed it in detail before. You can check our previous post:11 Causes Of Copper Wire Breakage.

For more information about wire drawing dies, please contact us.

E-mail: [email protected]