Products

Learn more about the Changsha 3 Better Ultra-Hard Materials Co. Ltd products.

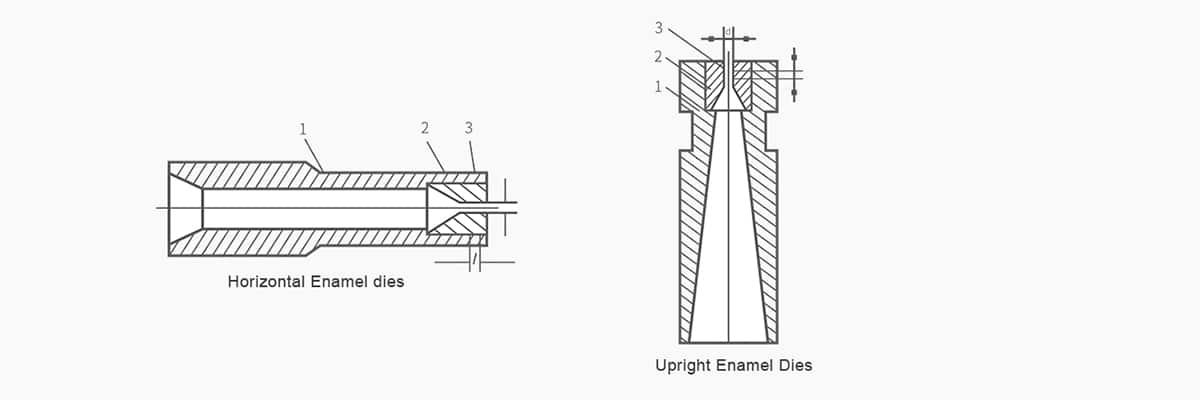

Enameling Dies

The enameling dies to use high-quality natural diamonds, polycrystalline and tungsten carbide as raw materials, and the special inlay process ensures the out-of-roundness of each mold and the inlay position of the mold core, the inner hole tolerance is precise, the finish is good, and there is no paint leakage.

| Full Name: | Enameling dies |

|---|---|

| Size: | Hole diameters: 0.16 – 5.20 mm (larger or smaller size customized according to customer requirements) |

| Material: | Stainless steel outer case+ Tungsten carbide/PCD die blank |

Description

| Full Name: | Enameling dies |

|---|---|

| Size: | Hole diameters: 0.16 – 5.20 mm (larger or smaller size customized according to customer requirements) |

| Material: | Stainless steel outer case+ Tungsten carbide/PCD die blank |

The Description of Enameling Dies

The enameling dies to use high-quality natural diamonds, polycrystalline and tungsten carbide as raw materials, and the unique inlay process ensures the out-of-roundness of each mold and the inlay position of the mold core, the inner hole tolerance is precise, the finish is good, and there is no paint leakage.

The Advantages of Enameling dies

- 1、The enameling die has perfect contour and leak-proof design to ensure uniform coating, smooth and continuous flow of enameled, and high insulation performance of wires.

- 2、The paint layer on the wire surface is uniform, and the tolerance is precise.

- 3、It is widely equipped with various domestic or imported enameling machines.

- 4、High wire insulation performance.

The Specification of Enameling dies

| Enameling Dies sizes | ||

| Size Range | Standard Tolerance | Minimum Tolerance |

| 0.040-0.150 | 0.0010 | 0.0005 |

| 0.151-0.300 | 0.0020 | 0.0010 |

| 0.301-0.500 | 0.0030 | 0.0015 |

| 0.501-1.000 | 0.0040 | 0.0020 |

| 1.001-1.500 | 0.0050 | 0.0030 |

| >1.500 | 0.0060 | 0.0030 |

The Application of Enameling dies.

This enameling dies are widely used in horizontal、vertical, and stranding enameling machines. It is suitable for copper enameled wire, aluminum enameled wire and other electromagnetic wire requiring painting.

Production Process of Enameling dies

|

Production Process of Enameled Wire |

||

| 1 | Annealing Oven | The bare wire is annealed to achieve the necessary softness of copper |

| 2 | Enamel Applicator | The enamel is applied in many single layers by the applicator (up to 30) to ensure good adhesion of the enamel to the copper conductor and ensure a suitable insulation property. |

| 3 | Curing Oven | In the oven, solvents are driven out of the enamel by heat |

| 4 | Lubrication Application | Lubrication is for the finished enamel surface to obtain good slidability |

| 5 | Laser O.D. Control | The laser will continuously control the outer diameter |

| 6 | Tension Control | Control the winding tension closely |

| 7 | Spooling | The wire is evenly spooled on the supply spool with consistent tension |

| 8 | Monitor | Continuous production data to the operator provided by the Monitor |