Products

Learn more about the Changsha 3 Better Ultra-Hard Materials Co. Ltd products.

Cobalt-based PCD Dies

PCD Wire Drawing Dies (polycrystalline wire drawing dies) with Cobalt base is a good product with close performance to imported polycrystal.

| Full Name: | PCD Cobalt-based Wire Drawing Dies(Polycrystalline diamond drawing dies) |

|---|---|

| Size: | Hole 0.04mm-35mm (larger or smaller size customized according to customer requirements) |

| Material: | Stainless steel outer case+Diamond (Co base)die blank |

Description

| Full Name: | PCD Cobalt-based Wire Drawing Dies(Polycrystalline diamond drawing dies) |

|---|---|

| Size: | Hole 0.04mm-35mm (larger or smaller size customized according to customer requirements) |

| Material: | Stainless steel outer case+Diamond (Co base)die blank |

The Description of PCD Cobalt-Based Drawing Dies

Polycrystalline diamonds are made of diamond micro-powder and metal catalysts in high-temperature and high-pressure environments. They have excellent wear resistance and high hardness. Based on different binders, PCD drawing die cores can be divided into cobalt-based and silicon-based.

Cobalt-based PCD drawing die blanks have metal bonding agents and good machining performance. They can be processed by EDM, laser, ultrasonic, and other processes suitable for processing and use under conditions of less than 650 ℃. PCD die Co base has two die blanks: self-supporting and tungsten carbide-supported die blanks.

The Advantages of PCD Cobalt-Based Drawing Dies

- Cobalt-based PCD wire drawing die blank contains metal bonds and has good processing properties.

- Can use electric sparks, lasers, ultrasonic, and other processes for processing

- The presence of metal cobalt makes it easy for diamonds to graphite at high temperatures.

- PCD die blank is suitable for processing and use at less than 650 degrees Celsius conditions

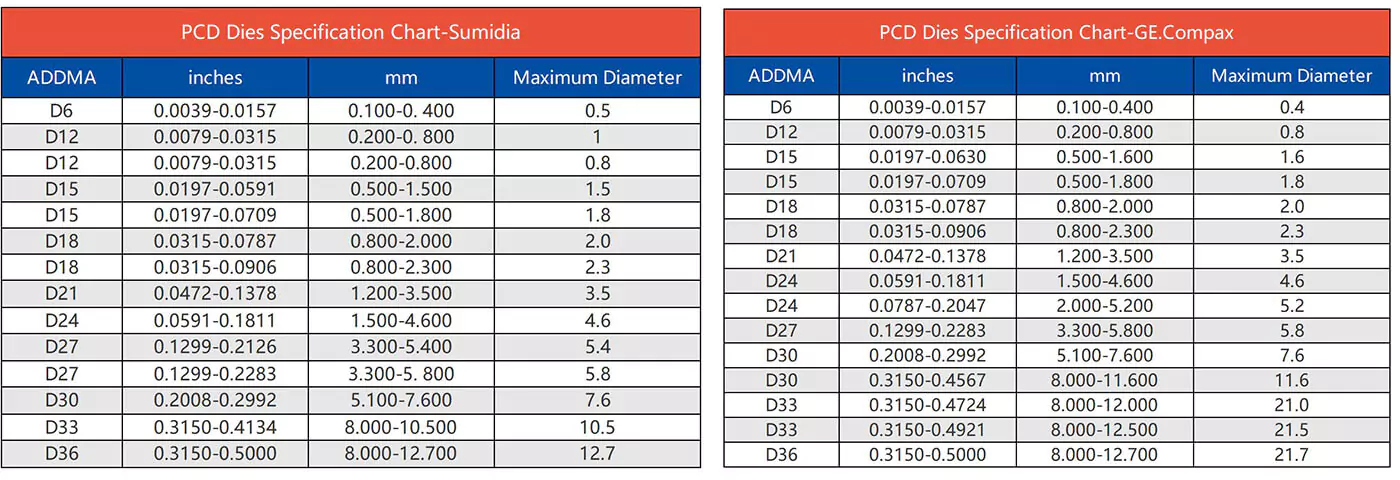

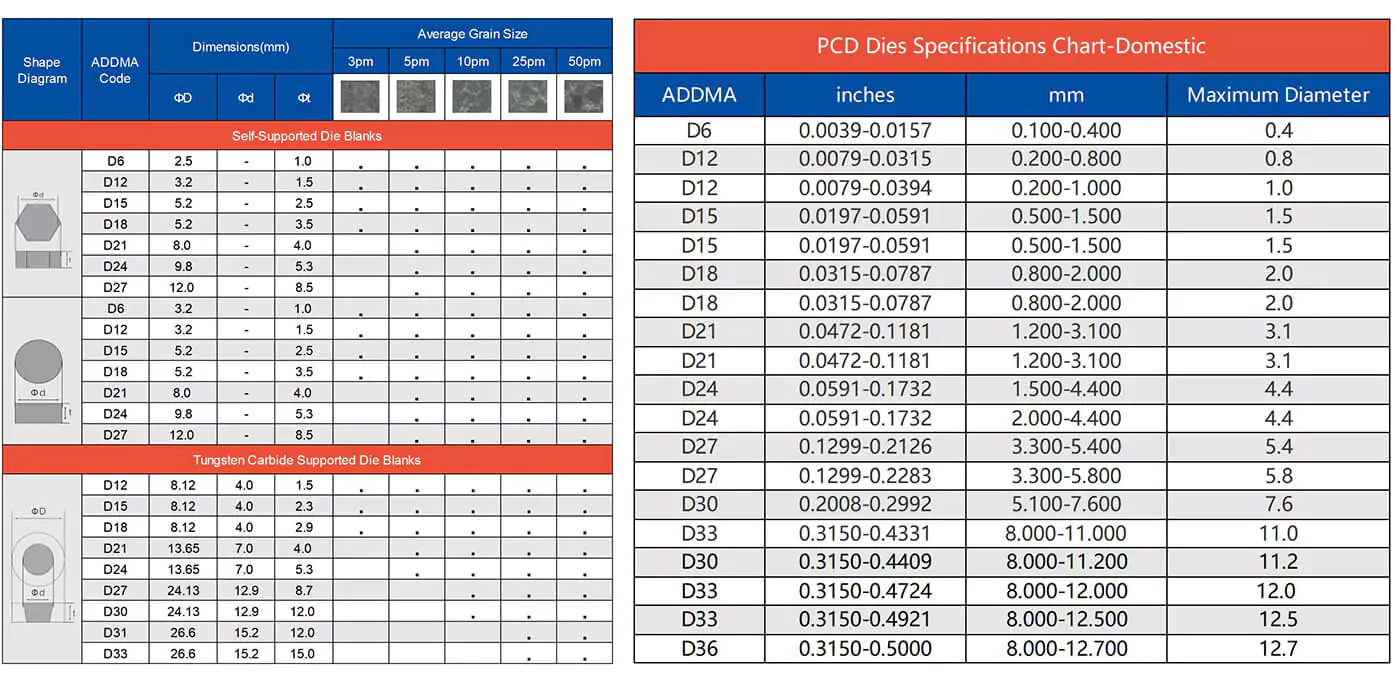

The Specification of PCD Cobalt-Based Drawing Dies

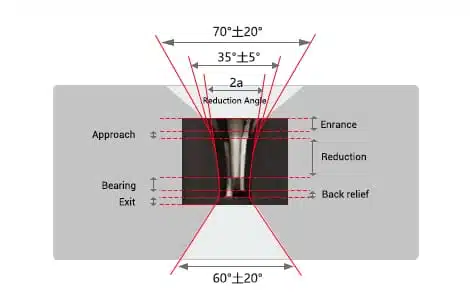

| Reduction Angles & Bearing Length of PCD Drawing Dies | |||||||

| Elongation | Area Reduction | Bearing Length | Lead Zinc, Silver Gold | Hard-Alalloys Nickel Copper | Brass Cualloys Stainless Steel | High Carbon Steel | Hot Tungsten |

| 5-9% | 5-8% | 0.2-0.5d | 14° | 10° | 9° | 8° | 10° |

| 9-14% | 8-12% | 0.2-0.5d | 16° | 12° | 13° | 10° | 10° |

| 14-19% | 12-16% | 0.4-0.8d | 18° | 14° | 13° | 12° | 12° |

| 19-33% | 16-25% | 0.4-0.8d | 22° | 18° | 16° | 15° | 12° |

| 33-54% | 25-35% | 0.4-0.8d | 24° | 22° | 19° | 18° | 14° |

The Application of PCD Cobalt-Based Drawing Dies

It can be used in all wet and dry drawing processes and is suitable for all applications, from large to ultra-fine drawings.

Flexible wire: copper wire, aluminum wire, brass wire, gold wire, aluminum magnesium alloy, copper-clad steel wire, etc.

Hardwires include stainless steel wire, copper-plated steel wire, copper-plated wire, tungsten wire, molybdenum wire, cutting wire, chromium wire, and nickel wire.

Test Report of PCD Cobalt-Based Drawing Dies

Report viewing and downloading: Test-report-of-PCD-wire-drawing-die-Conoptica.pdf