Products

Learn more about the Changsha 3 Better Ultra-Hard Materials Co. Ltd products.

TC Wire Drawing Dies

Tungsten carbide wire drawing dies are used in various drawing applications where diamond wire drawing dies are not economical or hole tolerances are less critical. They are widely used in the steel and non-ferrous metal industries, such as bundled or twisted large-diameter cables.

| Full Name: | TC drawing dies(Tungsten Carbide Wire Drawing Dies) |

|---|---|

| Size: | Hole 0.15mm-55mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | 45# steel outer case+Tungsten Carbide die blank |

Description

| Full Name: | TC drawing dies(Tungsten Carbide Wire Drawing Dies) |

|---|---|

| Size: | Hole 0.15mm-55mm (larger or smaller size smaller to be customized to customer requirements) |

| Material: | 45# steel outer case+Tungsten Carbide die blank |

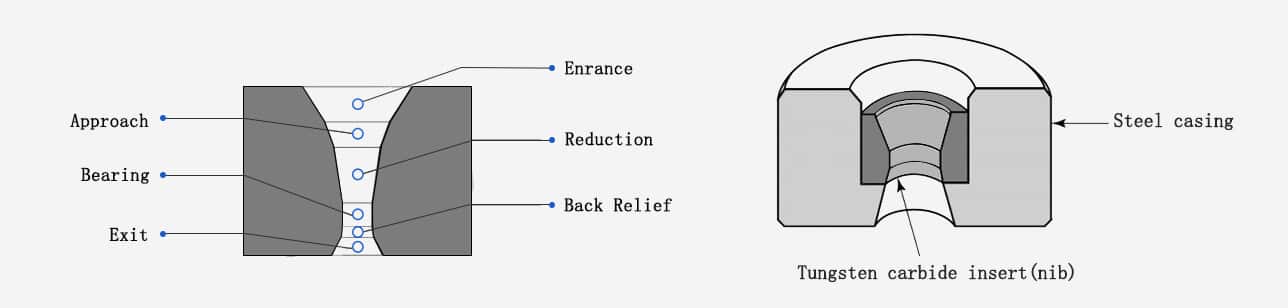

The Description of Tungsten Carbide drawing dies.

Tungsten carbide wire drawing dies, also known as cemented carbide wire drawing die (tungsten steel die), abbreviated as WC or TC, It is composed of tungsten carbide particles and metal cobalt. Tungsten carbide is a kind of non-oxidizing cemented carbide, which can maintain hardness similar to corundum or gem even at very high temperatures.

The Advantages of Tungsten carbide drawing dies

- High hardness, good thermal conductivity, and low coefficient of friction.

- It is low-cost and is used in some highly lossy, hard wire processing processes.

- The tungsten carbide module can withstand a high temperature of 2800 degrees C.

- The hardness of the carbide dies is compared to lower than the PCD dies.

- Low energy consumption, High corrosion resistance.

The Specification of Tungsten carbide drawing dies.

| Tungsten carbide drawing dies sizes | |||

| Die Blank Size(mm) | Hole Size(mm) | Die Blank Size(mm) | Hole Size(mm) |

| Φ13*10 | 0.40-2.10 | Φ25*18 | 5.70-8.70 |

| Φ16*14 | 2.11-3.10 | Φ30*22 | 7.70-11.50 |

| Φ22*18 | 3.11-6.00 | Φ35*25 | 9.70-14.00 |

| Φ30*21 | 6.01- 10.50 | Φ40*27 | 12.50-17.50 |

| Φ40*25 | 10.51-16.50 | Φ12.7*11.4 | 0.80-4.60 |

| Φ50*28 | 16.60-26.00 | Φ15.8*15.2 | 0.80-5.30 |

| Φ60*35 | 26.10-36.00 | Φ18*17.7 | 1.00-8.90 |

| Φ75*35 | 36.10-50.00 | Φ19.5*19.5 | 5.80-9.00 |

| Φ90*35 | 50.01-60.00 | Φ25.4*20.8 | 8.80-12.30 |

| Φ12*8 | 0.80-2.70 | Φ30.1*20.8 | 9.00-15.00 |

| Φ15*10 | 1.30-4.50 | Φ38.1*25.4 | 11.50-17.30 |

| Φ20*14 | 3.50-6.40 | ||

The Application of Tungsten carbide drawing dies.

Tungsten steel mold is widely used on occasions that need high-temperature resistance and impact resistance and only needs short-term use. It is an excellent choice for manufacturing ferrous metals. Its main applications are Steel wire, stainless steel wire, copper wire, aluminum wire, tungsten wire, and other ferrous and non-ferrous metal wire types.

The Shapes/drawing Reference of Tungsten carbide drawing dies.

| Elongation | Area Reduction | Bearing Length | Lead Zinc, Silver Gold | Hard-Alalloys Nickel Copper | Brass Cualloys Stainless Steel | High Carbon Steel | Hot Tungsten |

| 5-9% | 5-8% | 0.2-0.5d | 14° | 10° | 9° | 8° | 10° |

| 9-14% | 8-12% | 0.2-0.5d | 16° | 12° | 13° | 10° | 10° |

| 14-19% | 12-16% | 0.4-0.8d | 18° | 14° | 13° | 12° | 12° |

| 19-33% | 16-25% | 0.4-0.8d | 22° | 18° | 16° | 15° | 12° |

| 33-54% | 25-35% | 0.4-0.8d | 24° | 22° | 19° | 18° | 14° |