Welding Wire - Solutions

In welding wire production, wire drawing dies play a key role in drawing thicker wires through multi-stage die holes, gradually reducing the diameter to obtain the desired diameter and smooth surface of the wire.

Welding Wire-To-Wire Dies

Typically, we advise our partners like this.

Quality, longevity and economic efficiency are the three points that usually concern us the most.

Carbon Steel Solid wire

Used for welding carbon and mild steels. Common types include ER70S-3, ER70S-6, and ER70S-7.

- Often the choice is to use a high-quality, robust and wear-resistant drawing wire dies such as Tungsten Carbide or CVD coating.

Stainless Steel Solid Wire

Used for welding stainless steel. Common types include ER308, ER309, and ER316.

- Stainless steel wires usually have high mould requirements. Usually, Tungsten Carbide or nano wire drawing moulds are used.

Aluminum&Copper Welding Wire

Used for welding aluminum &copper and aluminum &copper alloys. Common types include ER4043 and ER5356.

- Copper and aluminium are similar and are softer metals. The choice of die material can include rugged, wear-resistant tungsten steel or nano-drawing dies.

Nickel Alloy Welding Wire

Used for welding nickel alloys such as Inconel and Hastelloy. Common specifications include ERNiCr-3, ERNiCrFe-2, etc.

- Nickel alloys are usually harder, so harder wire drawing dies can be used. Nano-diamond CVD coating drawing dies are recommended.

Hardfacing Welding Wire

Used for hard-facing applications to improve wear resistance. Common types include chromium-carbide and complex carbide alloys.

- Usually, wire drawing dies with excellent abrasion resistance are used. Nano-diamond CVD coating or PDC drawing dies are recommended.

Flux-Cored Welding Wire

Contains a flux core to provide the protection required during the welding process. Classified into gas-shielded and self-protected types. Common specifications include E71T-1, E70T-4, etc.

- Usually, it depends on the combination of core and shell. Nano-diamond CVD coating or PDC drawing dies are recommended.

Wire Drawing dies for Welding Wire

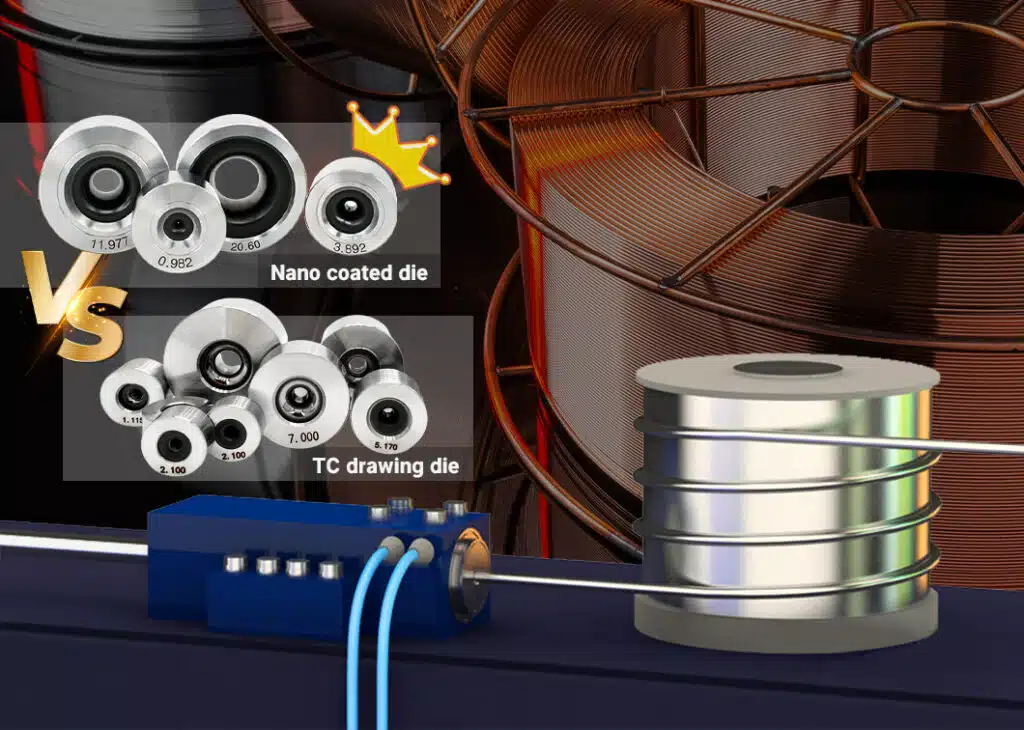

Upgrading Revolution

In the welding wire industry, carbide wire drawing dies have long been favoured for their economic efficiency. Nevertheless, with the advancements in nano-coating technology over the years, the cost-effectiveness of nano-coated dies has surpassed that of carbide counterparts. Consequently, carbide wire drawing dies have been entirely replaced by the more economical nano-coated alternatives.

- Improved Wear Resistance

- Reduced Friction

- Enhanced Hardness

- Improved Chemical Resistance

- Enhanced Thermal Stability

Our happy customers

We have helped many welding wire factories to save costs.

Depending on the wire material and process. Reduces overall costs by an average of 5% after talking to engineers.

M.Tauqeer

United Arab Emirates

after using the CVD nano drawing die. our machine has been running normally.

my guy said that the frequency of wire die change has been reduced a lot. thanks.

Fajar Insani Indah

Indonesia

We haven’t crunched the numbers on the total cost just yet, but we’re expecting a nice drop. On the bright side, we’ve got a boost in gloss, and the wire breakage issue is officially sorted. Big thanks, my friend!

Mali

Thailand

Yes. we have calculated the cost of production. It is currently down by 3.7%. wI’ll also improve the lubricant. thank you very much

Cost reduction processes

in welding wire industry!

1

Tell us exactly what you need

Just tell us the production size, and specification, or give us the drawing. If there are other needs, you can also feel free to put forward. Satisfying customers’ needs is our most basic principle.

2

We'll plan the perfect move for you

When we receive your request. Our sales will be in touch with you. Solutions are researched based on your production needs. We will provide you with a feasibility analysis and an optimisation plan. Production plan for customer’s needs. Production lead time is usually 3-15 working days.

3

Continuous Support and Improvement!

Once you’ve received and used the product for a while, our sales team will conduct periodic follow-up visits. We’ll also implement ongoing optimization programs to enhance product performance and align with your production cycle.

You ask, we answer

These Q&As may address some of your concerns.

We ensure favourable raw material prices by establishing long-term relationships with reliable suppliers, which in turn affects the cost of the final product.

At the same time, scientific management practices are a way for us to reduce costs and maintain the quality of our products.

Finally, because we are a manufacturer, we avoid the cost of intermediate links.

The commitment of the production workshop is 3~15 working days (no special circumstances).

For small order, Express will be the best, And for bulk order, sea ship way is best but take longer time. For urgent orders, we suggest via air to airport or by Express send to your door.

We are an official partner of DHL. It usually takes only 3-5 days after sending by DHL.

We are leading manufacture in wire drawing dies which has experience for more than 13 years.

We are ISO-9001 and ISO-14001 certified.

100% QC inspection before shipment.

If needed. We can offer the Conoptica testing report for each dies.

While instances like these are exceptionally rare due to our stringent quality control, we assure you that we prioritize the protection of your rights. If, unfortunately, any issue arises, we sincerely apologize.

For the first year from the date of purchase, should any problem arise on our end, we commit to a swift response. We will cover the shipping costs and promptly send a replacement to ensure your satisfaction.

Ready to cost reduction?

Let’s navigate this cost-reduction journey together, ensuring a sustainable and prosperous future for your enterprise.